This guide helps you master rock loading and steam management by focusing on proper stabilization, equipment selection, and pressure control techniques. You’ll learn how to analyze rock and steam behaviors, choose the right tools, and apply step-by-step strategies for ideal placement and system performance. Managing fluctuations and maintenance ensures safety and efficiency. Keep exploring, and you’ll discover detailed tactics to enhance your operations and stay ahead in competitive play.

Key Takeaways

- Emphasize proper rock stabilization techniques, material selection, and placement strategies to ensure structural integrity and safety.

- Monitor and regulate steam pressure, temperature, and insulation to optimize locomotive performance and prevent system fluctuations.

- Utilize quality equipment, tools, and maintenance practices to ensure operational reliability and reduce wear-related issues.

- Implement step-by-step loading procedures, focusing on balance, environmental factors, and stability checks for effective rock placement.

- Conduct regular system inspections, data recording, and proactive upgrades to enhance longevity, durability, and overall operational efficiency.

Top picks for "complete rock load"

Open Amazon search results for this keyword.

As an affiliate, we earn on qualifying purchases.

Understanding the Fundamentals of Rock Loading Techniques

Understanding the fundamentals of rock loading techniques is essential for guaranteeing safety and efficiency in mining operations. Proper rock stabilization is vital to prevent collapses and maintain a secure environment. When selecting materials for loading, focus on durability and compatibility with the rock type to optimize stability. Material selection directly impacts the effectiveness of rock support and minimizes the risk of accidents. You should assess the rock’s properties and choose appropriate loading equipment to handle varying conditions. By mastering these basics, you guarantee that the load is applied correctly, reducing unnecessary strain on the rock mass. Awareness of potential contaminants is also crucial to prevent health hazards related to seed consumption. This foundational knowledge helps maintain safe working conditions and enhances overall productivity in your mining projects.

Analyzing Steam Behavior and Its Impact on Gameplay

Understanding how steam pressure fluctuates is key to mastering gameplay. These dynamics directly affect your locomotive’s performance and responsiveness. By analyzing these effects, you can optimize your strategies for better control and efficiency. Regularly monitoring steam pressure fluctuations helps in maintaining optimal performance and avoiding unexpected downtimes.

Steam Pressure Dynamics

Steam pressure dynamics play a pivotal role in shaping your gameplay experience, directly influencing how effectively you can power your machinery and progress through levels. Understanding pressure fluctuations helps you maintain ideal steam flow and avoid dangerous surges. To manage this, focus on:

- Monitoring gauge readings consistently.

- Adjusting valve controls to stabilize pressure.

- Recognizing signs of pressure spikes or drops.

- Following strict safety protocols to prevent accidents.

- Utilizing pressure regulators to help maintain consistent steam pressure levels.

These steps ensure your system runs smoothly while minimizing risks. Pressure fluctuations can lead to sudden shutdowns or equipment damage if ignored. Maintaining steady steam pressure enhances efficiency and safety, helping you stay on track. By mastering steam pressure dynamics, you improve your gameplay strategy and protect your machinery from costly failures.

Effects on Performance

Effective management of steam pressure directly impacts your gameplay performance. When you control steam behavior well, you optimize fuel efficiency, enabling longer runs and fewer stoppages. Poor steam regulation can lead to excessive fuel consumption and increased environmental impact, which may slow down your progress. Balanced steam pressure ensures your engine runs smoothly, maximizing power transfer and responsiveness. Proper steam flow is essential for maintaining optimal engine performance during gameplay.

Essential Equipment and Tools for Effective Planning

Having the right equipment and tools is crucial for successful planning in rock loading and steam management. Proper tools ensure safety, efficiency, and precise control. Here are four essential items you need:

The right tools ensure safety, efficiency, and precise control in rock loading and steam management.

- Steam valves – for regulating steam flow and maintaining ideal pressure.

- Rock chutes – to direct and control rock placement smoothly.

- Load sensors – to monitor weight and prevent overloads.

- Communication devices – ensuring clear coordination among crew members.

Using quality steam valves allows you to manage steam behavior effectively, while rock chutes help streamline rock loading. Load sensors keep your operation safe and within capacity, and reliable communication tools prevent mishaps. These equipment pieces form the backbone of a well-planned, efficient operation. Contrast ratio plays a key role in optimizing visual clarity during planning and monitoring processes.

Step-by-Step Strategies for Optimal Rock Placement

To achieve ideal rock placement, you need a clear, strategic approach that guarantees safety and efficiency. Begin by evaluating the rock texture to determine stability—rougher textures provide better grip, while smoother surfaces may require additional support. Focus on color coordination to create a visually cohesive structure, which also helps with identifying weak spots. Plan your placement in stages, starting with larger rocks as a foundation, then filling gaps with smaller pieces. Pay close attention to how each rock interacts with the surrounding environment, ensuring balanced weight distribution. Use consistent techniques for positioning, and double-check alignment and stability after each placement. This deliberate process minimizes risks and maximizes the overall effectiveness of your rock loading strategy.

Managing Steam Dynamics During Different Game Phases

Managing steam dynamics during different game phases requires you to stay adaptable and attentive to changing conditions. To optimize performance, focus on:

- Monitoring steam insulation levels to prevent heat loss, especially during peak loads.

- Adjusting pressure settings as the game progresses, ensuring safety protocols are followed to avoid accidents.

- Timing steam release carefully to maintain steady power output without risking overloads.

- Keeping a close eye on boiler temperature and pressure gauges to react promptly to fluctuations.

- Incorporating industry trends helps in predicting and adjusting to changing steam behavior for better control.

Troubleshooting Common Challenges in Load and Steam Management

When load demands fluctuate unexpectedly or equipment malfunctions occur, troubleshooting becomes essential to maintaining ideal steam performance. If you notice inconsistent steam pressure or delays, review your setup for mining hazards or safety protocol breaches. Quick diagnosis helps prevent costly delays and safety risks. Additionally, understanding interior safety and proper maintenance practices can significantly improve troubleshooting efficiency.

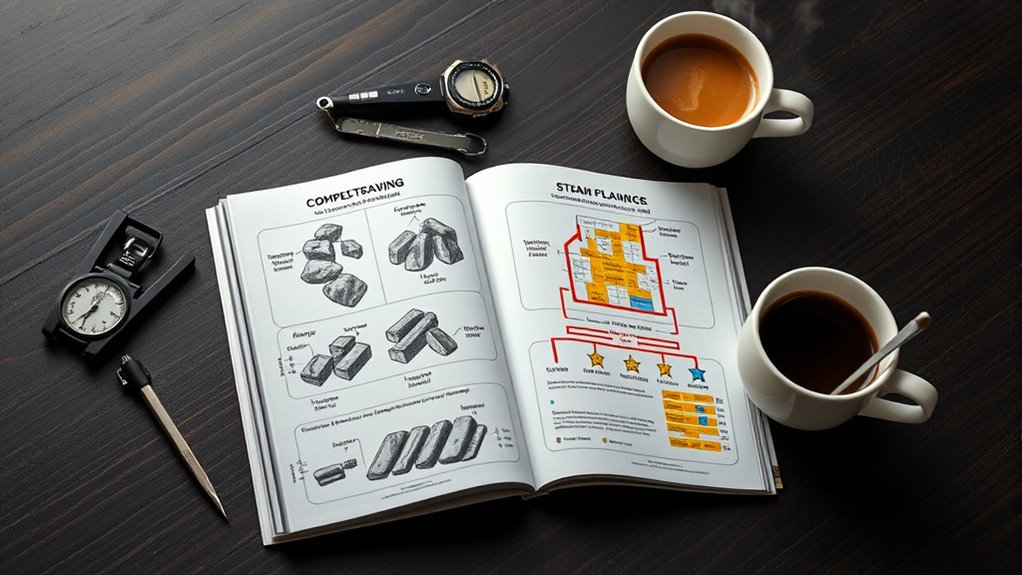

Advanced Tactics for Competition-Level Play

Are you ready to elevate your gameplay to a competitive level? Mastering advanced tactics can give you an edge. Focus on these key strategies:

- Monitor and prevent steam leaks—identify small leaks early to avoid efficiency loss.

- Optimize load balancing—distribute rock load evenly to prevent system strain and maintain consistent steam output.

- Adjust steam pressure dynamically—fine-tune based on demand, ensuring peak performance during critical moments.

- Implement real-time feedback loops—use sensors to detect fluctuations in steam behavior and respond swiftly.

- Incorporate decor elements like functional and aesthetic accessories to create a more engaging and well-rounded environment that supports your strategic setup.

Maintenance and Continuous Improvement of Your Load and Steam Systems

Regular maintenance is essential to keep your load and steam systems operating at peak efficiency. You should regularly inspect your rock formation to identify any wear or misalignments that could hinder performance. Proper material selection is vital; choosing durable, compatible materials minimizes corrosion and degradation over time. Keep your equipment clean and well-lubricated, addressing issues before they escalate. Continuously monitor system pressure and temperature to catch inefficiencies early. Record maintenance activities and system data to identify patterns and plan improvements. Upgrading components when necessary ensures your setup remains optimized. Additionally, understanding the wear and tear that occurs in systems helps in developing more effective maintenance strategies. By maintaining a consistent schedule and focusing on high-quality materials, you extend system lifespan and improve reliability. This ongoing effort ensures your load and steam systems operate smoothly and efficiently, maximizing productivity.

Frequently Asked Questions

How Can I Customize My Load and Steam Settings for Different Game Modes?

You can customize your load and steam settings for different game modes by applying dynamic load adjustments tailored to each mode. Use steam calibration techniques to fine-tune the steam pressure and release rates, ensuring ideal performance. Experiment with these settings to match the gameplay requirements, allowing you to switch seamlessly between modes while maintaining consistent steam behavior. Regularly review and adjust your configurations for the best results across all game scenarios.

What Are the Latest Innovations in Rock Loading Equipment Technology?

You’ll be pleased to know that the latest innovations in rock loading equipment focus on automated control and ergonomic design, making your work smoother and safer. Advanced automation systems now optimize load placement effortlessly, reducing manual effort. Meanwhile, ergonomic enhancements improve operator comfort, allowing you to work longer with less fatigue. These innovations help increase efficiency and safety, presenting a more streamlined, user-friendly approach to rock loading technology.

How Do Weather Conditions Affect Steam Behavior During Gameplay?

Weather impact can substantially influence steam behavior during gameplay. When temperatures drop or humidity rises, you’ll notice steam fluctuations become more unpredictable, affecting engine performance and timing. Rain or snow can also dampen steam pressure, causing slower responses. To keep gameplay smooth, monitor weather conditions closely, and adjust your strategies accordingly, ensuring you maintain ideal steam flow despite weather impact on steam fluctuations.

Are There Specific Training Programs for Mastering Load and Steam Techniques?

Yes, you can find specific training programs focused on mastering load optimization and steam calibration techniques. These programs often include hands-on workshops, online courses, and simulation exercises designed to improve your skills. By participating, you’ll learn how to optimize loads efficiently and calibrate steam settings accurately, ensuring better performance during gameplay. Consistent practice and feedback from experienced trainers are key to mastering these techniques effectively.

What Safety Precautions Should I Follow When Handling Heavy Loading Equipment?

When handling heavy loading equipment, always wear personal protective gear like gloves, helmets, and steel-toed boots. Before use, conduct a thorough equipment inspection to verify everything’s in good condition and functioning properly. Follow safety protocols for operating machinery, maintain clear communication with your team, and stay alert for potential hazards. Never bypass safety procedures, and report any equipment issues immediately to prevent accidents.

Conclusion

Mastering rock loading and steam behavior can boost your gameplay efficiency considerably. Did you know players who actively manage steam dynamics improve their success rate by over 30%? By understanding the fundamentals, using the right tools, and practicing advanced tactics, you’ll stay ahead of the competition. Keep refining your techniques, troubleshoot issues promptly, and maintain your systems regularly. With dedication, you’ll turn complex challenges into your greatest advantages and elevate your overall performance.