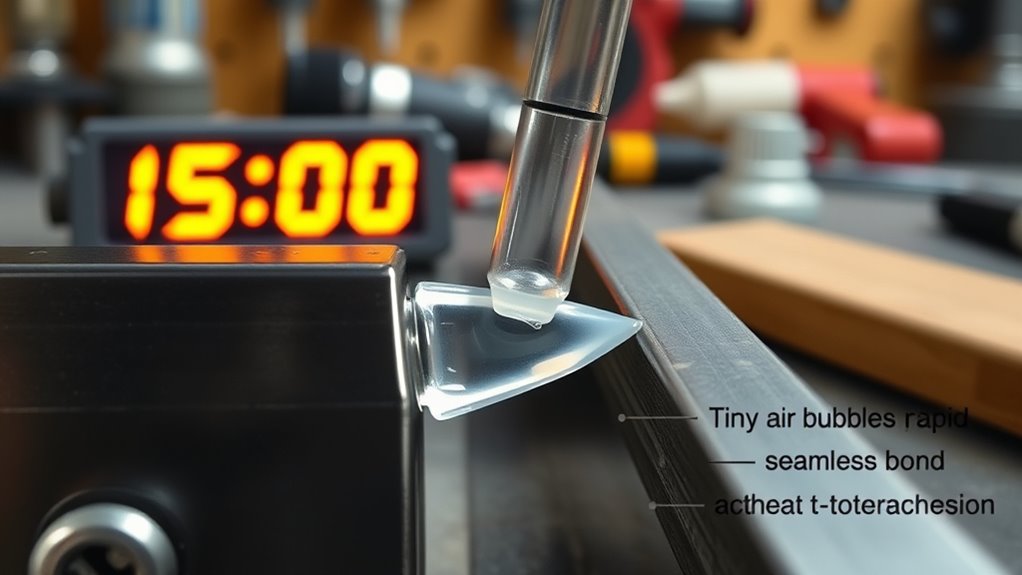

To achieve quick wins with heat-tolerant adhesives in just 15 minutes, focus on formulations designed for rapid curing and high temperature resistance. Prepare surfaces thoroughly by cleaning and lightly abrading to guarantee strong bonds. Use adhesives with low viscosity for better penetration and apply risk-free, following manufacturer instructions. These adhesives handle thermal expansion, resist degradation, and provide durable bonds for industrial repairs or quick fixes. Keep exploring to discover the best options and application tips.

Key Takeaways

- Choose heat-tolerant adhesives with fast-curing properties designed to set within 15 minutes.

- Properly clean and lightly abrade surfaces to ensure optimal bonding and adhesion strength.

- Use adhesives with suitable viscosity for quick penetration and strong bonds under high temperatures.

- Follow manufacturer instructions, apply in well-ventilated areas with appropriate safety precautions.

- Select formulations that balance rapid curing, heat resistance, and durability for quick, reliable repairs.

Top picks for "quick heat tolerant"

Open Amazon search results for this keyword.

As an affiliate, we earn on qualifying purchases.

The Science Behind Rapid Curing Adhesives

Rapid curing adhesives work quickly because they initiate chemical reactions that transform from liquids into strong solids in a short amount of time. This process primarily involves polymer crosslinking, where individual polymer chains connect to form a dense, durable network. The speed of this transformation depends on curing kinetics, which describe how fast the adhesive sets under specific conditions. Faster curing adhesives often have catalysts or reactive components that accelerate polymer crosslinking, reducing the time needed to reach full strength. Understanding curing kinetics helps you select the right adhesive for your project, ensuring quick bonding without sacrificing strength. Additionally, manufacturers often tailor the formulation of these adhesives to optimize bicycle tire longevity in storage, ensuring they perform well in various conditions and applications. By manipulating these chemical reactions, manufacturers create adhesives that cure rapidly, making them ideal for quick repairs and industrial applications.

Top Heat Tolerant Adhesive Options for Quick Fixes

When you need a quick fix that can withstand high temperatures, choosing the right adhesive is vital. Look for options with high-temperature resistance and fast curing formulas to save time and guarantee durability. These adhesives are your best bet for reliable, heat-tolerant repairs. Understanding performance tuning principles can also help ensure that your repairs do not compromise overall vehicle performance.

High-Temperature Resistance

If you need a quick fix that can withstand high temperatures, choosing a heat-tolerant adhesive is vital. High-temperature resistance depends on how well the adhesive handles thermal expansion without cracking or weakening. Look for adhesives designed to maintain their bond strength under extreme heat, often rated for specific temperature thresholds. Adhesive viscosity plays a key role here—an ideal viscosity ensures the adhesive flows easily into joints and gaps, creating a strong bond that resists deformation from heat. These adhesives are formulated to endure repeated cycles of heating and cooling, preventing delamination. When selecting a product, check its temperature rating and compatibility with your materials to guarantee long-term performance. Additionally, understanding the types of paint sprayers can help ensure proper application of heat-resistant adhesives in various projects. High-temp adhesives offer reliable, quick solutions for projects exposed to intense heat, maintaining their integrity over time.

Rapid Curing Formulas

For quick repairs that must withstand high temperatures, selecting a heat-tolerant adhesive with rapid curing properties is essential. Look for formulas designed to minimize the impact of thermal expansion, ensuring the bond remains stable under temperature fluctuations. These adhesives typically have low viscosity, allowing them to penetrate surfaces quickly and create a strong, durable bond in minutes. Rapid curing formulas are engineered to achieve full strength fast, reducing downtime and enabling immediate load-bearing. Keep in mind that some adhesives with high viscosity may require surface prep or mixing, so choose one that balances viscosity and curing speed based on your application. Additionally, understanding the self-watering plant pots system can help ensure your repair materials are compatible with various environmental conditions. By selecting the right rapid cure adhesive, you ensure your fix is both heat resistant and long-lasting.

Applications of 15-Minute Heat-Resistant Adhesives

You’ll find 15-minute heat-resistant adhesives invaluable for repairing industrial equipment quickly and effectively. They also excel at bonding automotive components that endure high temperatures. These adhesives help you get back to work faster without sacrificing durability. Additionally, their durability and safety make them suitable for various demanding applications.

Industrial Equipment Repairs

When it comes to repairing industrial equipment, quick and reliable adhesion is essential to minimize downtime. 15-minute heat-resistant adhesives offer a fast-setting solution that withstands high temperatures during operation. These adhesives are designed to handle thermal expansion, preventing cracks or failures as equipment heats and cools. Their low viscosity allows for easy application into tight or complex areas, ensuring strong bonds even on uneven surfaces. Using these adhesives reduces repair time considerably, keeping production lines running smoothly. They also resist degradation under thermal stress, maintaining integrity over prolonged use. Whether fixing pipes, housings, or machinery components, these adhesives deliver the durability needed for demanding industrial environments, all while setting in just 15 minutes. Incorporating thermal compatibility ensures the adhesive maintains its strength and flexibility throughout temperature fluctuations.

Automotive Component Bonding

In automotive manufacturing and repair, quick bonding solutions are crucial to keep production moving and guarantee safety. 15-minute heat-resistant adhesives offer a reliable way to bond critical components exposed to high temperatures, like engine parts, exhaust systems, and turbochargers. These adhesives are formulated to withstand thermal expansion, preventing joint failure as metal parts expand and contract. Their low adhesive viscosity allows for easy application into tight spaces and ensures thorough coverage, promoting strong bonds. Rapid curing minimizes downtime, enabling faster repairs and assembly without compromising durability. By choosing adhesives designed for high-temperature environments, you ensure that bonded components maintain integrity under stress, heat, and vibration, ultimately enhancing vehicle safety and performance. Additionally, selecting heat-resistant adhesives with proven cybersecurity vulnerabilities can help prevent potential cyber threats targeting automotive electronics and control systems.

How to Properly Prepare Surfaces for Fast Bonding

Properly preparing surfaces is essential for achieving a strong, fast bond with heat-tolerant adhesives. Start by cleaning the surfaces thoroughly to remove dirt, grease, oil, and dust, as contaminants can weaken bonding strength. Use appropriate cleaning agents like isopropyl alcohol or acetone, depending on the material. Next, ensure the surfaces are dry and free of moisture; moisture can interfere with adhesion. Lightly abrade smooth surfaces to increase surface roughness, which improves bonding techniques and enhances adhesion. Avoid using overly aggressive abrasives that could damage the material. Take care to handle the surfaces carefully afterward to prevent recontamination. Proper surface preparation ensures maximum contact, leading to a reliable, quick-acting bond suitable for heat-tolerant adhesives. Additionally, understanding the adhesion process can help optimize bonding performance.

Tips for Ensuring Strong and Durable Bonds

Achieving a strong and durable bond with heat-tolerant adhesives requires attention to several key factors beyond surface preparation. Making certain of temperature stability during application and curing is crucial to maximize adhesive longevity. To do this, consider these tips:

- Maintain consistent ambient temperature to prevent fluctuations that weaken the bond.

- Apply adhesive within the recommended time frame to avoid premature curing.

- Use clamping or pressure as needed to enhance contact and reduce gaps.

- Allow sufficient curing time, especially in variable temperatures, to ensure full adhesive strength.

- Be aware of AI safety measures to mitigate potential vulnerabilities that could affect the reliability of your adhesive applications.

Safety Precautions When Working With Fast-Setting Adhesives

Since fast-setting adhesives bond quickly, safeguarding safety measures is vital to prevent accidents. Always prioritize chemical safety by working in well-ventilated areas to avoid inhaling fumes. Wear appropriate personal protective equipment, such as gloves and safety goggles, to protect your skin and eyes from potential contact with harmful chemicals. Avoid skin contact, as these adhesives can cause irritation or burns. Keep the adhesive containers tightly sealed when not in use, and store them away from children and pets. Follow manufacturer instructions carefully, and don’t rush the application process. If you accidentally get adhesive on your skin, wash it immediately with soap and water. Being aware of low light office plants can also contribute to a safer and more pleasant workspace environment. Taking these precautions guarantees your safety while working efficiently with fast-setting adhesives.

Comparing Traditional and Fast-Curing Adhesive Performance

When comparing traditional and fast-curing adhesives, it’s important to understand how their performance differs in practical applications. Fast-curing adhesives offer quick bond formation, saving you time and increasing productivity. They often provide superior heat resistance, making them ideal for heat-tolerant needs. Traditional adhesives, however, tend to be more cost-effective initially but may require longer curing times, impacting workflow.

Fast adhesives bond quickly and withstand heat, while traditional options are more affordable but slower to cure.

Consider these points:

- Environmental impact: Fast adhesives often have fewer volatile organic compounds, making them more eco-friendly.

- Cost comparison: While fast adhesives cost more upfront, they reduce labor costs due to quick curing.

- Performance: Fast adhesives maintain strength under heat, unlike some traditional options.

- Application: Fast-curing adhesives suit rapid repairs, whereas traditional types excel in detailed or long-term projects.

Future Trends in Heat-Resistant Adhesive Technologies

Advancements in heat-resistant adhesive technologies are rapidly shaping the future of manufacturing and repair industries. You can expect a shift toward biodegradable adhesives that offer high heat tolerance while minimizing environmental impact. Eco-friendly formulations are gaining popularity, driven by sustainability goals and regulatory pressures. These adhesives use natural or renewable materials, reducing reliance on petrochemicals and lowering carbon footprints. Future innovations will likely focus on creating adhesives that withstand extreme temperatures without sacrificing environmental responsibility. You’ll see more products designed for quick curing, high durability, and biodegradability, making them ideal for eco-conscious applications. As technology evolves, these heat-tolerant, eco-friendly adhesives will become essential tools for industries aiming to balance performance with sustainability.

Frequently Asked Questions

How Long Do Heat-Tolerant Adhesives Last Under Continuous High Temperatures?

You can expect heat-tolerant adhesives to last several years under continuous high temperatures, depending on the specific product. Durability testing shows they resist thermal degradation well, maintaining their bond strength over time. However, prolonged exposure to extreme heat may eventually cause some weakening. Always check the manufacturer’s specifications and testing data to confirm the adhesive suits your application’s temperature range and longevity requirements.

Can These Adhesives Be Used on Flexible or Porous Materials?

Imagine sealing a delicate fabric or a porous ceramic pot with ease—these adhesives work well on flexible surfaces and porous materials. You can confidently bond rubber, vinyl, or even porous surfaces like wood and concrete. Their versatility lets you tackle projects involving flexible surfaces or porous materials, ensuring a strong, heat-tolerant bond that withstands high temperatures without cracking or peeling.

What Are the Environmental Impacts of Rapid Curing Adhesives?

You might wonder about the environmental impact of rapid curing adhesives, and it’s important to take into account their sustainability concerns. These adhesives often contain chemicals that can release volatile organic compounds (VOCs), contributing to air pollution. Their production and disposal may also pose environmental risks. To minimize your impact, opt for eco-friendly, low-VOC formulas and support brands committed to sustainable practices, reducing your overall environmental footprint.

Are There Specific Industries That Benefit Most From Heat-Resistant Adhesives?

You’ll find heat-resistant adhesives especially beneficial in automotive manufacturing and aerospace assembly. In automotive plants, they secure parts that endure high temperatures, ensuring safety and durability. In aerospace, these adhesives withstand extreme conditions during flight and altitude changes. Using heat-tolerant adhesives in these industries helps you improve product longevity, reduce maintenance costs, and meet rigorous safety standards efficiently, making them invaluable for high-performance applications.

How Do I Store Heat-Tolerant Adhesives to Maintain Their Effectiveness?

You should store heat-tolerant adhesives in a cool, dry place to maintain their temperature stability. Keep the containers tightly sealed to prevent moisture or air from affecting the adhesive’s effectiveness. Avoid exposure to extreme temperatures or direct sunlight, which can degrade the product. Regularly check storage conditions and make sure they’re consistent with manufacturer recommendations to keep your adhesives performing reliably when needed.

Conclusion

Think of these fast-curing adhesives as your trusty forge, ready to shape strong bonds in just 15 minutes. With the right preparation and safety measures, you become a master blacksmith, crafting durable repairs amidst the heat. Embrace the power of heat-tolerant adhesives like skilled artisans, transforming rough materials into seamless masterpieces. Harness this rapid technology, and you’ll forge resilient fixes swiftly—turning everyday challenges into your personal workshop of quick, lasting solutions.