To maintain heat tolerant adhesives effectively, store them in airtight containers in a cool, dry place away from sunlight. Always prepare surfaces by cleaning and roughening them as needed, and apply the adhesive evenly within recommended temperature ranges. Regularly inspect the bonds for signs of wear or damage, and replace adhesives that show deterioration. Proper maintenance guarantees durable, heat-resistant bonds—stay with us to discover more essential tips for long-lasting performance.

Key Takeaways

- Store adhesives properly in cool, dry, airtight containers to prevent degradation and maintain heat resistance.

- Prepare surfaces thoroughly by cleaning and roughening to ensure strong, durable bonds under heat exposure.

- Follow manufacturer instructions carefully during application, including temperature control and curing processes.

- Conduct regular inspections for signs of deterioration like cracks, peeling, or discoloration to ensure bond integrity.

- Keep detailed maintenance records, replace degraded adhesives promptly, and monitor performance to extend service life.

Understanding Heat Tolerant Adhesives and Their Properties

Heat tolerant adhesives are specially formulated to withstand high temperatures without losing their bonding strength. Their key properties include excellent temperature resistance, allowing them to perform reliably even in extreme heat. This means they won’t soften, melt, or become brittle when exposed to elevated temperatures. Additionally, these adhesives boast impressive chemical stability, which helps them resist degradation from chemicals, oils, or solvents often present in industrial environments. This stability ensures the adhesive maintains its integrity over time, providing a durable bond. Understanding these properties helps you select the right heat tolerant adhesive for your project, especially when working in conditions where temperature fluctuations and chemical exposure are common. By choosing adhesives with strong temperature resistance and chemical stability, you ensure long-lasting, reliable bonds. Vetted – Mother Baby Kids

Proper Storage Techniques to Extend Adhesive Lifespan

To maximize the lifespan of your heat tolerant adhesives, proper storage is crucial. Maintaining the right conditions prevents premature deterioration and ensures excellent performance. Focus on storage tips that include controlling the temperature, as heat or cold can compromise adhesive quality. Keep adhesives in a cool, dry place away from direct sunlight and humidity. Always seal containers tightly after use to prevent air exposure. Consider using airtight, weatherproof containers to enhance temperature control and avoid contamination. Additionally, store adhesives upright to prevent leaks and ensure easy access. Proper storage techniques not only extend the adhesive’s lifespan but also guarantee reliable bonding when needed. Regularly check stored adhesives for signs of hardening or separation, and replace if necessary. Temperature control is especially important for maintaining the adhesive’s effectiveness over time.

Preparing Surfaces for Optimal Adhesion and Durability

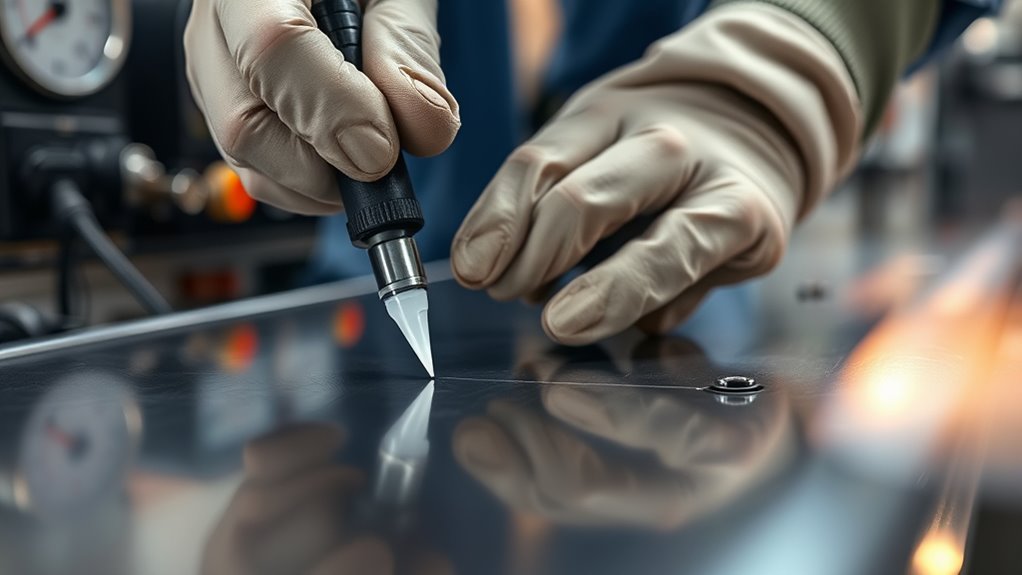

Preparing surfaces properly is essential for achieving strong, durable bonds with heat-tolerant adhesives. First, you should clean surfaces thoroughly to remove dirt, grease, and debris, ensuring nothing interferes with adhesion. Use a suitable cleaner and wipe the area dry. Next, surface roughening is vital; lightly abrade smooth surfaces with sandpaper or a wire brush to create a textured profile. This increases the surface area for bonding and improves grip. Make sure to remove any dust or residue from roughening before applying the adhesive. Proper surface preparation minimizes the risk of bond failure and enhances the adhesive’s heat resistance. Additionally, understanding automation technology can help streamline the preparation process in industrial settings, ensuring consistency and efficiency. By focusing on cleaning surfaces and surface roughening, you set the foundation for a reliable, long-lasting bond that performs under high temperatures.

Applying Heat Tolerant Adhesives Correctly for Best Results

For the best results, it is crucial to follow the manufacturer’s instructions carefully when applying heat tolerant adhesives. Proper application guarantees ideal adhesive curing and reliable performance under heat. Start by applying the adhesive evenly and within the recommended temperature range, as temperature regulation is key to achieving strong bonds. To enhance results:

- Keep surfaces clean and dry before application to promote proper adhesion.

- Use a compatible applicator to avoid excess or uneven spread.

- Monitor and control the environment’s temperature during curing to prevent premature setting or weak bonds.

- Selecting the right adhesive type ensures that it maintains its heat-tolerant properties over time.

Routine Inspection and Maintenance to Ensure Performance

You need to regularly check the condition of your heat-tolerant adhesives to maintain their performance. Visual inspections help you spot any signs of wear, damage, or deterioration early on. Monitoring the adhesive’s condition guarantees you catch issues before they affect the bond’s strength. Incorporating celebrity lifestyle insights can inspire innovative ways to approach maintenance routines.

Regular Visual Checks

Regular visual checks are essential for maintaining the performance of heat-tolerant adhesives. You should regularly inspect the bonded areas for signs of wear, discoloration, or peeling, which could indicate issues with adhesion or temperature exposure. Pay close attention to color matching, ensuring the adhesive’s appearance remains consistent, as changes might signal deterioration. Also, check for any damage that could compromise the bond, and ensure proper disposal methods are adhered to for expired or damaged adhesives to prevent hazards. Incorporating vetted textile techniques can help optimize the longevity and effectiveness of adhesive bonds.

- Look for cracks, bubbles, or peeling that could weaken the bond

- Ensure the color remains uniform, indicating ongoing stability

- Confirm disposal methods are correctly followed for waste materials

Monitor Adhesive Conditions

Routine inspection and maintenance are essential to guaranteeing heat-tolerant adhesives perform reliably over time. Regularly monitor the adhesive conditions by checking for signs of deterioration, such as cracks, peeling, or discoloration. Review your adhesive formulations to confirm they meet the specific temperature demands of your application, and verify application techniques were properly followed during installation. Pay close attention to how the adhesive responds under heat exposure, and note any changes in bond strength or flexibility. Keeping a detailed record of inspections helps identify patterns and determine when reapplication or adjustments are needed. Staying vigilant about adhesive conditions allows you to catch issues early, maintain ideal performance, and extend the lifespan of your heat-tolerant adhesives. Additionally, understanding the core personality traits associated with reliability and resilience can help in selecting optimal adhesives for challenging environments.

Troubleshooting Common Issues With Heat Tolerant Adhesives

Despite their durability, heat tolerant adhesives can sometimes present issues that hinder their performance. Common problems include poor adhesion, which may result from improper surface preparation or incompatible packaging design. You might also notice adhesive failure due to excessive heat exposure or incorrect application techniques. To troubleshoot effectively, consider these factors: seasonal variations can influence adhesive effectiveness, so adjusting application methods accordingly is advisable. – Surface cleanliness and compatibility** – Application temperature and curing time – Packaging design and adhesive branding consistency** Ensuring surfaces are clean and suitable for the adhesive is essential. Verify that application methods align with manufacturer instructions. Also, review your packaging design to prevent heat exposure that could compromise adhesion. Properly managing these aspects helps maintain ideal performance of heat tolerant adhesives.

Frequently Asked Questions

How Long Do Heat Tolerant Adhesives Typically Last Before Replacement?

Heat tolerant adhesives typically last between 2 to 5 years, depending on conditions like temperature exposure and application quality. You should monitor their durability lifespan regularly, as extreme heat or frequent cycles can shorten their effectiveness. The replacement timeline varies; if you notice peeling, cracking, or reduced adhesion, it’s time to replace them. Proper maintenance guarantees they perform well and extend their lifespan, preventing costly damage or failures.

Can Heat Tolerant Adhesives Be Used on Porous or Flexible Surfaces?

Yes, heat tolerant adhesives can be used on porous surfaces and flexible materials. Imagine bonding rubber or fabric in high-temperature environments—you can rely on these adhesives to maintain strong, durable bonds. They’re designed to accommodate the movement of flexible materials and penetrate porous surfaces effectively. Just make certain you choose the right adhesive formulation for your specific porous or flexible surface, to get the best, long-lasting results.

Are There Environmentally Friendly Options for Heat Resistant Adhesives?

Yes, there are environmentally friendly options for heat resistant adhesives. You can opt for biodegradable options that break down naturally, reducing environmental impact. Look for eco-friendly formulations that use plant-based or non-toxic ingredients, ensuring safety for both the environment and your projects. These adhesives perform well under heat while helping you stay eco-conscious. Always check product labels for certifications or claims related to sustainability and biodegradability.

What Safety Precautions Should Be Taken During Application?

Remember, safety first! When applying heat-tolerant adhesives, always wear personal protective equipment like gloves and goggles to protect your skin and eyes. Make certain your work area is well-ventilated to avoid inhaling fumes. Keep a fire extinguisher nearby and follow manufacturer instructions carefully. By prioritizing work area safety and using proper protective gear, you minimize risks and ensure a safe, successful application process.

How Do Temperature Fluctuations Affect Adhesive Performance Over Time?

Temperature fluctuations cause thermal expansion and contraction, which can weaken your adhesive over time. As temperatures change, the repeated stress can lead to adhesive fatigue, reducing its bond strength. You’ll notice gaps or peeling if the adhesive can’t withstand these shifts. To maintain performance, guarantee the adhesive is suitable for your temperature range and consider using flexible formulations that accommodate thermal expansion and contraction.

Conclusion

By mastering maintenance, minimizing mishaps, and monitoring your heat-tolerant adhesives, you’ll maximize their performance and prolong their lifespan. Stay savvy with surface prep, storage, and inspections, and solve sticky situations swiftly. Consistent care creates a confident, corrosion-free connection that endures extreme temperatures. Keep these key qualities in mind, and you’ll conquer common concerns with clarity and confidence, ensuring your adhesive applications stay strong, sturdy, and superbly successful every time.