Biofilm prevention involves keeping surfaces dry, clean, and using coatings with antimicrobial properties to inhibit microbial attachment. Regular cleaning and disinfection help remove bacteria and disrupt biofilm development. Using materials less prone to biofilm formation and applying biological methods like natural antimicrobials can also be effective. Advances like nanotechnology, electrical disruption, and sensors offer innovative controls. To learn more about effectively managing biofilms, explore the strategies that best suit your environment.

Key Takeaways

- Regular cleaning and disinfection remove biofilm buildup and prevent microbial attachment on surfaces.

- Applying surface coatings with antimicrobial or anti-adhesive properties inhibits initial biofilm formation.

- Controlling moisture and water flow reduces environments conducive to biofilm development.

- Utilizing biological agents like natural antimicrobials or probiotics can disrupt biofilm growth sustainably.

- Emerging technologies such as nanocoatings, electric fields, and sensors offer advanced biofilm prevention methods.

What Are Biofilms and Why Are They Problematic?

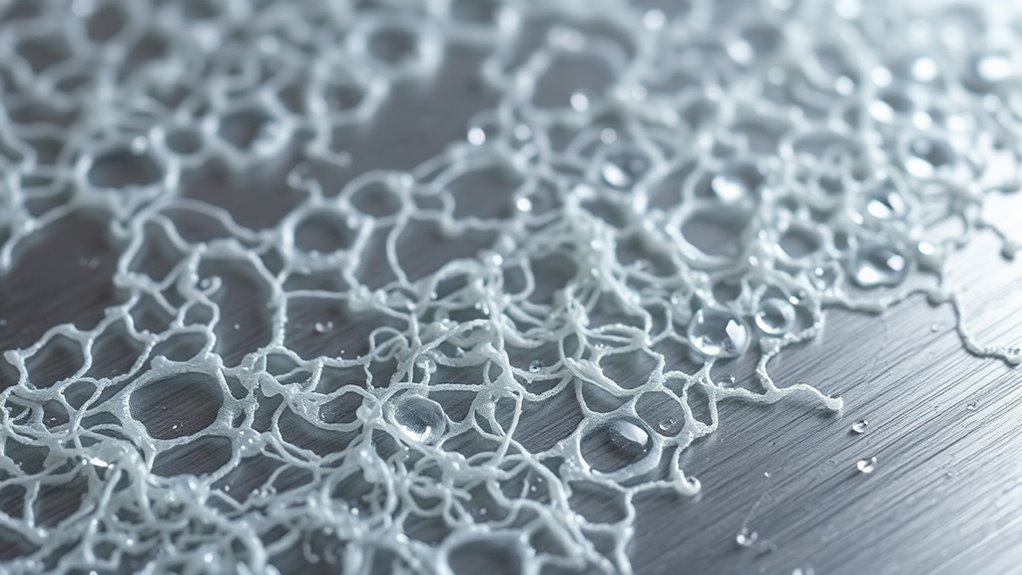

Biofilms are complex communities of microorganisms that stick to surfaces and produce a slimy, protective matrix. This matrix shields the microbes inside, making them highly resistant to cleaning agents and antibiotics—a phenomenon known as biofilm resistance. Because of this resistance, biofilms are difficult to eliminate once established. The microbial communities within biofilms work together, sharing nutrients and protecting each other from threats. This cooperation enhances their survival and allows them to thrive in environments where free-floating bacteria would struggle. You’ll find biofilms forming on everything from medical devices to pipes and teeth, often leading to persistent infections and equipment failures. Understanding why biofilms are problematic helps you appreciate the importance of effective prevention strategies.

How Do Biofilms Form on Surfaces?

Biofilm formation begins when free-floating microorganisms attach to a surface, often through weak, reversible interactions such as electrostatic forces or van der Waals attractions. This initial step is known as surface adhesion, where microbes make contact and stick temporarily. Once attached, they start microbial colonization, multiplying and producing a sticky extracellular matrix that anchors them more securely. This matrix protects the microbes from environmental stresses and helps them communicate, facilitating further growth. As the biofilm matures, the microbial community becomes more complex, with different species collaborating and forming a resilient, structured community. Understanding how microbes initially adhere to surfaces and begin colonization is key to developing strategies for effective biofilm prevention. Additionally, environmental factors such as pollutant accumulation can influence biofilm development, making it a multifaceted challenge to control.

What Are Common Environments Where Biofilms Develop?

You’ll often find biofilms forming in high-humidity areas where moisture persists. Water-related surfaces like pipes, sinks, and tanks are prime spots for biofilm development. Recognizing these environments helps you take steps to prevent their growth. Additionally, self-watering plant pots can sometimes create localized moisture that fosters biofilm formation if not maintained properly.

High-Humidity Areas

High-humidity environments create ideal conditions for biofilm development, as moisture promotes microbial adhesion and growth on surfaces. To prevent this, effective humidity control is essential to limit microbial activity. By maintaining proper indoor humidity levels, you can considerably reduce the risk of biofilms forming. Focus on these key areas:

- Bathrooms and kitchens, where moisture from daily activities fosters biofilm growth.

- Basements and crawl spaces, prone to persistent dampness and mold development.

- HVAC systems, which can circulate moisture-laden air, supporting microbial colonies.

Implementing humidity control measures helps inhibit biofilm formation and aids mold prevention. Regular cleaning and ventilation are crucial to maintaining a dry environment, ultimately protecting your space from microbial buildup and ensuring healthier indoor air quality.

Water-Related Surfaces

Water-related surfaces are common hotspots for biofilm development because moisture provides a perfect environment for microbial colonies to thrive. You’ll find biofilms forming in drinking water systems, where stagnant or slow-moving water encourages bacterial growth. Plumbing systems, especially pipes and faucets, are prime locations for biofilm buildup due to constant moisture exposure. These biofilms can protect bacteria from disinfectants and make removal challenging. Other areas like water tanks, cooling towers, and showerheads also promote biofilm formation. When water remains in contact with surfaces over time, it creates ideal conditions for microbes to adhere and multiply. Regular cleaning and maintenance of these surfaces are essential to prevent biofilm development and ensure water safety. Additionally, filtration systems can help reduce microbial presence and inhibit biofilm growth in water supply lines.

What Strategies Can Prevent Biofilm Formation?

Preventing biofilm formation requires implementing targeted strategies that disrupt the initial attachment and growth of microorganisms. One effective approach involves applying surface coatings that inhibit microbial adhesion, making it harder for bacteria to settle and establish biofilms. Additionally, incorporating antimicrobial agents into these coatings provides ongoing protection by killing or suppressing microorganisms before they mature. To enhance prevention, consider these strategies:

- Use advanced surface coatings infused with anti-adhesive or antimicrobial properties.

- Regularly replace or upgrade coatings to maintain effectiveness.

- Combine coatings with other control methods, like antimicrobial agents, for a multi-layered defense.

- Selecting toilet materials that resist bacterial growth can further reduce biofilm development on surfaces.

How Do Cleaning and Disinfection Help Control Biofilms?

Have you ever wondered how cleaning and disinfection effectively control biofilms? They do so by removing surface roughness and disrupting the protective matrix that biofilms create. Cleaning physically removes dirt, debris, and microbial buildup, reducing surface roughness where biofilms tend to form. Disinfection then uses chemical agents, like disinfectants, to kill remaining microorganisms and break down biofilm structures. Regular cleaning minimizes opportunities for biofilms to develop, while proper disinfection ensures that lingering bacteria are eliminated. These processes are essential because biofilms are resistant to many cleaning methods if not properly addressed. Volkswagen Tuning techniques can also involve specialized procedures to ensure thorough removal of contaminants. By combining mechanical cleaning with effective chemical agents, you markedly reduce biofilm formation, maintaining a safer and more hygienic environment.

What Materials Are Less Susceptible to Biofilm Development?

Certain materials naturally resist biofilm formation because their surface properties make it difficult for microorganisms to adhere and establish colonies. These materials often have smooth, non-porous surfaces or are treated with advanced surface treatments. Incorporating antimicrobial coatings can further reduce biofilm development by actively killing bacteria on contact. When selecting materials, consider:

Materials with smooth, non-porous surfaces and antimicrobial treatments naturally resist biofilm formation.

- Stainless steel with antimicrobial surface treatments for durability and reduced microbial adhesion

- Certain plastics, such as polyethylene or polypropylene, which are less prone to biofilm buildup

- Glass surfaces enhanced with antimicrobial coatings that inhibit microbial attachment and growth

Additionally, selecting biocompatible and non-porous materials can significantly improve resistance to biofilm development, ensuring a cleaner, safer environment.

Are There Biological Methods to Inhibit Biofilm Growth?

Biological methods offer promising strategies to inhibit biofilm growth by harnessing natural or engineered microorganisms, enzymes, and other biological agents. Natural antimicrobials, produced by certain bacteria or plants, can disrupt biofilm formation without harmful chemicals. These substances interfere with microbial communication or weaken cell structures, preventing biofilm establishment. Probiotic applications also show potential by introducing beneficial bacteria that outcompete harmful microbes, reducing biofilm development on surfaces. This approach fosters a balanced microbial environment that naturally limits pathogen colonization. Using biological methods can be environmentally friendly and sustainable, minimizing reliance on chemical disinfectants. Additionally, understanding the trustworthiness of biological agents is essential to ensure their safe application. Incorporating natural antimicrobials and probiotics into cleaning protocols provides an innovative, effective way to control biofilms and maintain cleaner, safer environments.

How Can Regular Maintenance Reduce Biofilm Risks?

Regular maintenance plays a crucial role in reducing biofilm risks by preventing the buildup of microbial communities on surfaces. Consistent cleaning removes debris and reduces nutrients that foster biofilm development. Applying surface coatings with antimicrobial agents enhances this protection by creating a hostile environment for microbes. To maximize effectiveness, consider these steps:

Regular maintenance and antimicrobial coatings are essential for preventing biofilm buildup and ensuring surface hygiene.

- Regularly clean surfaces with appropriate disinfectants to disrupt early biofilm formation.

- Use surface coatings embedded with antimicrobial agents for ongoing microbial resistance.

- Schedule routine inspections to identify and address potential biofilm hotspots before they become problematic.

- Maintaining proper surface conditions, such as controlling moisture levels, further inhibits biofilm formation and promotes a healthier environment.

What Are Emerging Technologies for Biofilm Prevention?

Are emerging technologies transforming how we prevent biofilm formation? Absolutely. Innovations like nanotechnology coatings create ultra-thin, durable barriers that inhibit microbial adhesion. Electric field disruption applies controlled electrical currents to prevent biofilm buildup on surfaces. These methods are promising for industries like healthcare and water treatment. Here’s a quick overview:

| Technology | Mechanism | Benefits |

|---|---|---|

| Nanotechnology Coatings | Create anti-adhesive surfaces | Long-lasting, non-toxic |

| Electric Field Disruption | Uses electrical currents to repel microbes | Rapid, effective prevention |

| Photocatalytic Surfaces | Break down biofilm with light energy | Environmentally friendly |

| Ultrasound Waves | Disrupt biofilm structure | Non-invasive, safe |

| Smart Sensors | Detect early biofilm formation | Enables prompt intervention |

These emerging technologies offer innovative, efficient solutions for biofilm control. Research into biofilm prevention methods continues to advance, highlighting the importance of innovative solutions.]

Frequently Asked Questions

Can Biofilm Prevention Techniques Be Environmentally Friendly?

Yes, biofilm prevention techniques can be environmentally friendly. You can use eco-friendly solutions that minimize chemical impact, like natural antimicrobials or biodegradable cleaners. Adopting sustainable practices, such as regular cleaning and proper maintenance, reduces reliance on harsh chemicals. These methods help prevent biofilm growth while protecting the environment. By choosing eco-friendly solutions and sustainable practices, you guarantee effective biofilm control without harming ecosystems or human health.

How Do Biofilms Impact Human Health Beyond Industrial Settings?

Biofilms greatly impact your health beyond industrial settings by fostering microbial resistance, making infections harder to treat. When biofilms form on medical devices or in your water systems, they can harbor harmful bacteria that cause persistent infections or illnesses. This increases health implications, including chronic infections and antibiotic resistance. To protect yourself, maintain good hygiene, guarantee proper sterilization of medical equipment, and stay informed about biofilm risks in your environment.

Are There Specific Certifications for Biofilm-Resistant Materials?

Yes, there are specific certifications for biofilm-resistant materials. You should look for certification standards like NSF, ANSI, or other industry-specific labels that verify a material’s biofilm resistance. These certifications guarantee that the material labeling clearly indicates its biofilm-resistant properties, helping you make informed decisions for applications where hygiene and microbial control are critical. Always verify the certification to ensure the material meets the necessary biofilm prevention standards.

What Is the Cost-Benefit Analysis of Biofilm Prevention Methods?

You should perform a cost comparison and effectiveness evaluation to determine the best biofilm prevention methods. While some approaches may have higher upfront costs, they can save you money over time by reducing maintenance and infection risks. Investing in effective solutions often leads to long-term benefits, including improved safety and compliance. Balancing initial expenses with ongoing savings helps you optimize your biofilm prevention strategy for maximum value.

How Do Biofilm Prevention Strategies Vary Across Industries?

You’ll find biofilm prevention strategies vary across industries like healthcare, food processing, and manufacturing. In healthcare, strict regulatory compliance demands rigorous, industry-specific cleaning to prevent infections, while food processing emphasizes sanitation to avoid contamination. Manufacturing may focus on surface treatments and regular monitoring. Understanding these differences helps you choose tailored prevention methods, ensuring effective biofilm control aligned with industry standards and regulatory requirements.

Conclusion

By understanding how biofilms form and the environments they thrive in, you can prevent their growth. While cleaning and advanced technologies offer powerful tools, regular maintenance and choosing resistant materials are your first lines of defense. Biofilms may be invisible threats lurking on surfaces, but with proactive measures, you can stay ahead. Remember, prevention isn’t just about cleaning; it’s about staying one step ahead of nature’s resilient communities.