To prevent bacteria and biofilm buildup in plunge tubing, you should clean regularly with EPA-approved disinfectants, following manufacturer instructions. Make sure to flush the tubing with fresh water after use and scrub gently with soft brushes to remove residue. Use non-porous, smooth materials like silicone or high-quality PVC for easier cleaning. Allow the tubing to dry completely after cleaning, and inspect frequently for signs of buildup. Continuing with these practices will help keep your system safe and bacteria-free.

Key Takeaways

- Regularly clean and disinfect tubing using EPA-approved sanitizers following manufacturer instructions.

- Flush tubing with fresh water after use to remove residual contaminants and prevent buildup.

- Use smooth, non-porous materials like silicone or high-quality PVC for easier cleaning and reduced biofilm formation.

- Inspect tubing regularly for signs of biofilm or mold and adjust cleaning routines accordingly.

- Ensure complete drying of tubing after cleaning to inhibit bacterial growth and biofilm development.

Plunge tubing, often used in spas and hot tubs, can quickly become a breeding ground for bacteria if not properly maintained. Bacteria thrive in the damp, warm environment of tubing, making regular sanitation essential. To effectively prevent bacterial buildup, you need to establish and follow strict sanitization protocols. These protocols involve regularly cleaning the tubing with appropriate disinfectants, ensuring that all surfaces are thoroughly treated. Using EPA-approved sanitizers designed for spa equipment helps eliminate harmful microorganisms and prevents biofilm formation. It’s important to adhere to manufacturer instructions regarding concentration and contact time to maximize effectiveness. Additionally, flushing the tubing with fresh water after use can help remove residual contaminants, reducing the risk of bacterial growth over time. Proper material selection also plays a critical role in preventing bacteria from establishing a foothold in plunge tubing. Opt for tubing made from non-porous, smooth materials like silicone or high-quality PVC, which are less likely to harbor bacteria and are easier to clean. Avoid porous or rough-surfaced materials, as they provide hiding spots for bacteria and biofilms, making sanitization more challenging. When choosing materials, consider their resistance to harsh disinfectants; some plastics can degrade or become damaged when exposed to frequent chemical treatments, compromising both cleanliness and structural integrity. Proper material selection ensures that your tubing remains easier to sanitize and less prone to bacterial colonization. Regular inspection for signs of mold, algae, or biofilm buildup is essential, as these can be indicators that your cleaning routine needs adjustment. Implement a routine schedule for draining, cleaning, and disinfecting the tubing, especially if the plunge tub is used frequently or stored for extended periods. Using a combination of mechanical cleaning—like gentle scrubbing with soft brushes—and chemical disinfectants creates a more effective barrier against bacteria. Also, remember to allow the tubing to dry completely after cleaning, as moisture promotes bacterial growth. Following proper installation and ventilation practices can further reduce the risk of bacterial proliferation in plunge tubing environments.

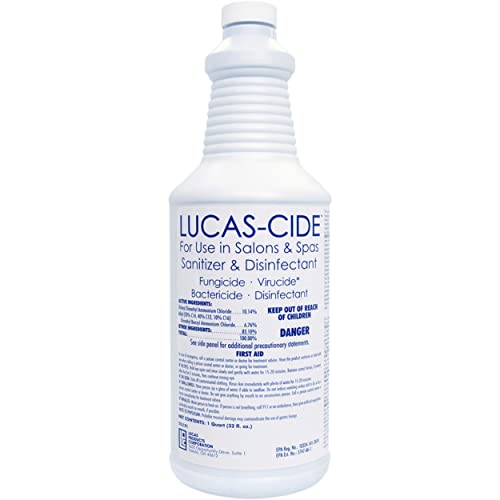

LUCAS-CIDE Salon and Spa Disinfectant, Hospital Grade, Blue, 32 Fl Oz

EPA‑approved hospital‑grade disinfectant trusted by salons & spas.

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Frequently Asked Questions

How Often Should Plunge Tubing Be Inspected for Contamination?

You should inspect plunge tubing for contamination at least weekly to guarantee early detection. Regular inspection frequency helps you identify any signs of bacteria or biofilm buildup promptly. Keep an eye out for discoloration, unusual odors, or blockages that indicate contamination detection. Consistent checks allow you to maintain a clean system, prevent biofilm development, and assure safe operation of the equipment. Adjust inspection frequency based on usage and risk factors for ideal results.

Are There Specific Disinfectants Recommended for Plunge Tubing?

Did you know bacteria can double every 20 minutes if unchecked? For plunge tubing, you should use approved disinfectant types like chlorine-based solutions, hydrogen peroxide, or quaternary ammonium compounds. Follow strict usage protocols, ensuring proper contact time and thorough rinsing. Regularly changing disinfectants and adhering to manufacturer’s instructions help prevent biofilm buildup. This way, you keep your tubing safe, clean, and free from harmful bacteria effectively.

Can Biofilm Formation Occur in New or Unused Tubing?

Yes, biofilm formation can occur even in new or unused tubing. Initial bacterial contamination from manufacturing or handling can settle inside the tubing, especially if it’s made from materials that promote bacterial adhesion. The tubing’s material effects, like surface texture and chemical properties, influence biofilm development. To minimize risks, thoroughly clean and disinfect new tubing before use, reducing the chance of bacteria establishing a biofilm.

What Are the Signs That Bacteria Are Developing in the Tubing?

You notice a cloudy or slimy film coating the inside of the tubing, like a faint mist obscuring clear glass. An unusual, foul odor lingers near the tubing, hinting at bacterial growth. These visual cues and odor detection are signs bacteria might be developing. If you observe discoloration or a persistent smell, it’s time to clean thoroughly, as biofilm buildup can lead to health risks and system malfunction.

How Does Temperature Affect Bacterial Growth in Plunge Tubing?

Temperature control directly impacts bacterial proliferation in plunge tubing. When the temperature is warm, bacteria grow faster, increasing the risk of biofilm formation. Cooler temperatures slow down this growth, helping you prevent bacteria from thriving. To keep your tubing safe, maintain ideal temperature levels, avoid fluctuations, and monitor regularly. This proactive approach minimizes bacterial growth, ensuring the tubing remains clean and reduces the chances of contamination.

1/4 " ID Silicone Tubing, JoyTube Food Grade Silicone Tubing 1/4" ID x 3/8" OD 10 Feet High Temp Pure Silicone Hose Tube for Home Brewing Winemaking

1/4" ID x 3/8" OD pre-cut flexible silicone tubing. High quality, flexible silicone compound in compliance with FDA…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Conclusion

To keep your plunge tubing free of bacteria and biofilm, stay vigilant with regular cleaning and proper disinfecting techniques. Don’t let problems fester; address them early before they grow out of hand. Consistent maintenance is your best weapon to stay ahead of the game. Remember, a stitch in time saves nine, so don’t put it off. By taking proactive steps, you’ll guarantee your equipment remains safe, clean, and ready when you need it most.

JUNZHIDA High Pressure Braided Clear Flexible PVC Tubing 3/4" ID,10ft

PVC tubing size: 3/4" ID,10ft; wall thickness: 2.5mm(come with 2 hose clamps); temperature range : 23°F to 149°F;…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

CPAP Tube Cleaning Brush-7 Feet Flexible + 7 Inches Handy Stainless Steel Wire Bristle Brush- Fits for Standard 22mm Diameter Tubing (Blue)

1. Soft brushes protect the tubing while effectively removing dirt and devris.

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.