To master heat-tolerant adhesives in a weekend, start by understanding their chemical properties and choosing the right types like high-temp epoxies or silicone-based options. Prepare surfaces carefully, ensuring they’re clean and dry, and gather the proper tools and safety gear. Follow manufacturer instructions closely for application and curing. Test your bonds under heat to confirm durability. Keep detailed notes, and if you keep exploring, you’ll gain the skills to excel in heat-resistant bonding.

Key Takeaways

- Understand adhesive chemical properties and choose high-temperature resistant types suitable for your materials.

- Prepare surfaces thoroughly by cleaning and priming to ensure strong, heat-resistant bonds.

- Follow manufacturer instructions precisely for application, curing conditions, and safety precautions.

- Test bonded assemblies under heat cycles to verify performance and identify potential weaknesses.

- Document results and refine techniques for continuous improvement in heat-tolerant adhesive mastery.

Understand the Basics of Heat Tolerant Adhesives

To effectively work with heat tolerant adhesives, you need to understand what sets them apart from standard adhesives. Their chemical properties allow them to withstand high temperatures without losing bonding strength or degrading. These adhesives often contain specialized polymers or resilient resins that resist heat-induced breakdown. Knowing the application techniques is vital—apply these adhesives in thin, even layers, and guarantee surfaces are clean and dry for optimal bonding. Some heat tolerant adhesives require specific curing methods or longer drying times to activate their heat resistance. By mastering the chemical properties and proper application techniques, you’ll guarantee a secure, durable bond that performs reliably under high-temperature conditions. This foundational knowledge helps you select and use heat tolerant adhesives effectively for your projects. Additionally, understanding store hours can be helpful when purchasing supplies, ensuring you have everything you need within your available shopping time.

Identify Suitable Adhesive Types for Your Projects

To choose the right heat-tolerant adhesive, you need to consider its high-temperature resistance and how well it matches your materials. Not all adhesives perform equally under heat, so selecting one that can withstand your project’s conditions is vital. Make sure to evaluate both the adhesive’s durability and material compatibility before making a decision. For specialized applications, such as heat-tolerant adhesives, understanding the specific temperature limits and compatibility requirements is essential for long-lasting results.

High-Temperature Resistance

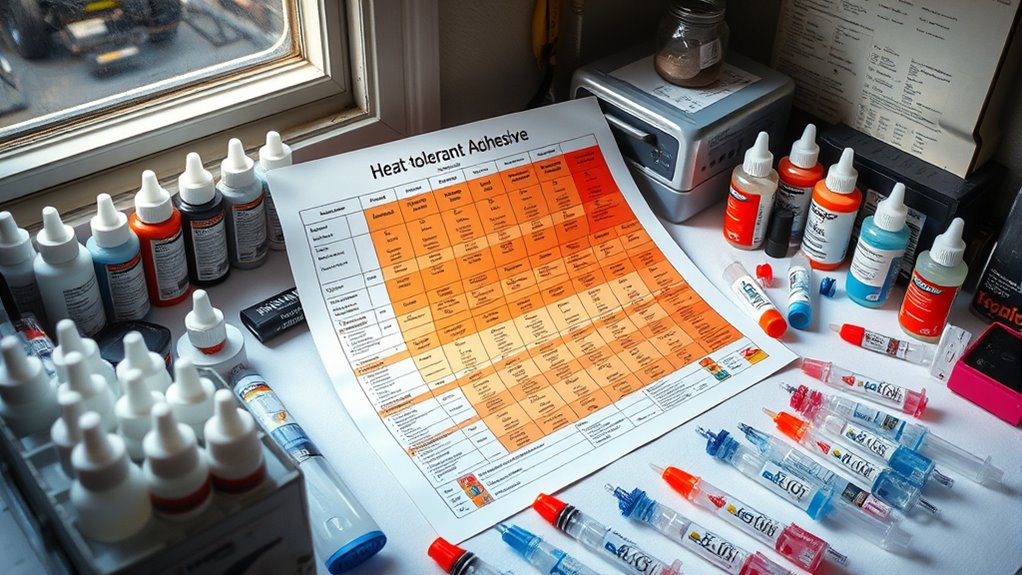

When selecting adhesives for high-temperature applications, it’s essential to choose types specifically designed to withstand intense heat without losing their bond strength. Look for adhesives that handle thermal expansion and maintain adhesive flexibility under heat stress. Some options include high-temperature epoxies, silicone-based adhesives, and ceramic adhesives, which excel in resisting heat while accommodating material movement. Here’s a quick comparison:

| Adhesive Type | Key Feature |

|---|---|

| High-Temperature Epoxy | Strong bond, heat resistant |

| Silicone Adhesive | Flexibility, thermal expansion |

| Ceramic Adhesive | Extreme heat tolerance |

| Phenolic Resin | Chemical resistance, high temp |

Choosing the right adhesive depends on your project’s specific demands for heat resistance and flexibility, ensuring a durable, long-lasting bond even in extreme conditions. Additionally, understanding heat tolerance of adhesives can help prevent failures in demanding environments.

Material Compatibility

Selecting the right adhesive depends heavily on the materials involved in your project. You need to consider chemical interactions to guarantee compatibility and avoid degradation over time. Some materials, like plastics and metals, may react negatively with certain adhesives, causing failure or weakening the bond. Environmental considerations also play a vital role; exposure to moisture, heat, or chemicals can affect adhesion quality. For example, an adhesive suitable for ceramic may not work well with rubber in high temperatures. Always check manufacturer guidelines for compatibility with your materials and environmental conditions. Testing a small area first helps confirm the adhesive’s performance. By understanding chemical interactions and environmental factors, you can choose an adhesive that provides reliable, heat-tolerant bonds suited to your specific project. Material compatibility is essential for ensuring long-lasting and effective bonds, especially under heat exposure.

Gather Essential Tools and Safety Equipment

Before you begin working with heat-tolerant adhesives, gather all the essential tools and safety equipment you’ll need. Start with a thorough tool kit that includes applicators, spatulas, and clamps to handle and position materials accurately. Safety gear is equally important; wear heat-resistant gloves, safety glasses, and a respirator if fumes are present. Confirm your workspace is well-ventilated and free of clutter to prevent accidents. Having the right tools will make application smoother and safer, reducing mistakes and ensuring a strong bond. Don’t overlook safety equipment, as working with high temperatures and adhesives can pose risks. Proper air quality considerations and ensuring good ventilation can help mitigate potential hazards. Preparing your tools and safety gear beforehand sets the foundation for a successful, safe adhesive application process.

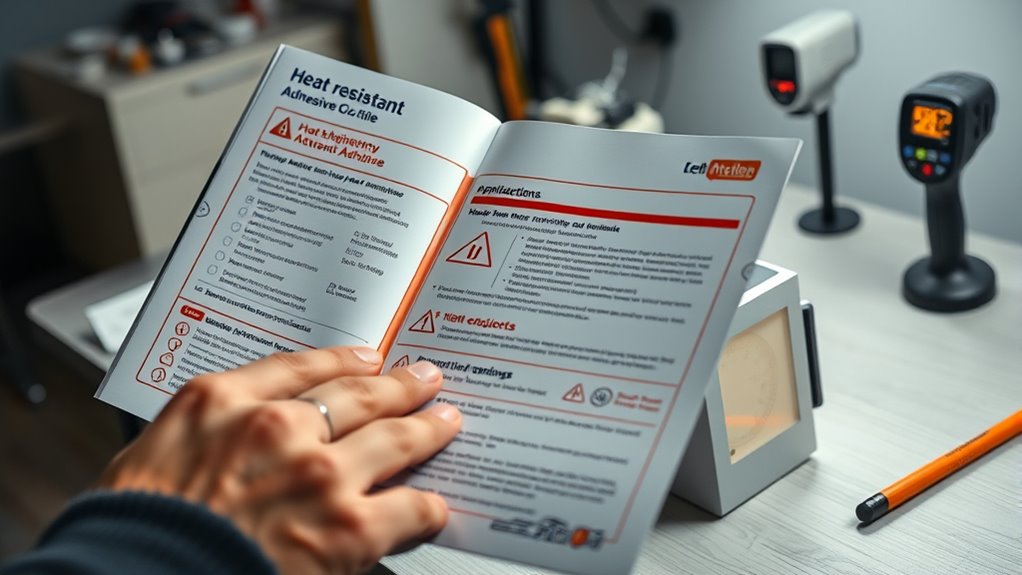

Read and Interpret Manufacturer Instructions Carefully

You need to read the entire label carefully to understand the proper application process. Highlight the key curing steps so you don’t miss any critical details. Also, pay close attention to the temperature and time specifications to guarantee ideal adhesive performance. Being aware of manufacturer guidelines ensures you follow best practices for optimal results.

Read Entire Label Carefully

Have you ever overlooked important details on a product label? Skipping this step can lead to using expired adhesive or missing critical temperature limits, risking failure. Carefully reading the entire label reveals essential info about adhesive shelf life, application temperature, and curing time. Remember, some adhesives change color as they set—this color change isn’t just visual; it signals proper curing. Ignoring instructions may cause you to underestimate required drying time or temperature, reducing heat resistance. Automation in business advancements are also impacting how adhesives are developed and tested for durability under varying conditions. Missing vital safety warnings that could harm you; Overlooking storage instructions that affect shelf life; Disregarding mixing ratios leading to weak bonds; Ignoring specific surface prep tips for durability; Forgetting the importance of curing conditions for heat tolerance. Read every detail to ensure your adhesive performs as expected, especially under high temperatures. This simple step safeguards your project’s success.

Highlight Key Curing Steps

Understanding and following the manufacturer’s curing instructions is essential for achieving maximum heat resistance. Carefully review the steps outlined, focusing on the specific curing process required for your adhesive. Proper curing ensures the bond develops ideal strength and durability. Highlight key steps such as recommended temperature, curing time, and any necessary surface preparation. Ignoring these instructions can weaken the bond, reduce heat tolerance, or cause failure. Use a checklist to ensure each step is completed accurately. Pay close attention to details like post-curing conditions or environmental factors that may impact the bond strength. Additionally, understanding heat-tolerant adhesives can help you select the right product for high-temperature applications. By prioritizing these key curing steps, you’ll maximize the adhesive’s performance and longevity under high heat conditions. Proper curing is the foundation for a reliable, heat-tolerant bond.

Note Temperature & Time Specs

Reading and interpreting the manufacturer’s temperature and time specifications is essential for ensuring a successful bond. Ignoring these details can lead to weak adhesion or failure under heat stress. Pay close attention to the temperature specifications, as exceeding or falling short can compromise the adhesive’s performance. Proper curing times are equally critical—rushing the process can weaken the bond, while over-curing might damage the materials.

- Feel confident in your application by following precise temperature guidelines

- Avoid costly mistakes that come from disregarding curing times

- Ensure your adhesive withstands high heat by adhering to specs

- Prevent bond failure caused by improper temperature control

- Achieve lasting results with accurate interpretation of manufacturer instructions

Prepare Surfaces for Optimal Bonding

To achieve a strong bond with heat-tolerant adhesives, you need to start by thoroughly preparing the surfaces. Begin with surface cleaning—remove dirt, grease, oil, and debris that can weaken adhesion. Use a suitable cleaner that won’t leave residues. Once clean, consider primer selection; choose a primer compatible with both the substrate and the adhesive. Applying the right primer enhances bonding strength, especially on porous or difficult surfaces. Guarantee the surface is dry and free of contaminants before priming. Proper surface preparation prevents bonding failures and assures the adhesive performs reliably under heat. Take the time to prepare meticulously—this step is vital for maximizing the adhesive’s heat resistance and long-term durability. Additionally, understanding the essential survival gear can help you better prepare for unexpected situations that might compromise your work environment or project safety.

Practice Application Techniques and Troubleshooting

Practicing proper application techniques is crucial to guarantee your heat-tolerant adhesive bonds effectively and withstands high temperatures. When you focus on precise application, you reduce errors and ensure a strong, durable bond. Managing stress and planning your project well are essential, as rushed work can lead to mistakes. Troubleshooting common issues quickly keeps your project on track and saves time. Remember, patience and attention to detail make all the difference. Here are key tips to refine your technique:

- Stay calm and focused during application

- Follow manufacturer instructions meticulously

- Monitor your workspace temperature and humidity

- Test small sections before full application

- Keep detailed notes for troubleshooting future projects

- Incorporate proper surface preparation to enhance adhesion and longevity

Test Adhesive Performance Under Heat Conditions

After honing your application techniques, it’s important to verify that your heat-tolerant adhesive performs reliably under actual conditions. To do this, test the adhesive layering by exposing your bonded materials to heat sources similar to real-world use. Observe how the adhesive reacts to thermal expansion, checking for signs of weakening or delamination. Ensure the adhesive maintains its integrity without cracking or losing adhesion, even when subjected to temperature fluctuations. Conduct controlled heat cycles to simulate prolonged exposure, noting any changes in bond strength. This step helps confirm that your adhesive can withstand the environment and prevents failures in critical applications. Proper testing ensures your application will perform reliably under heat stress, giving you confidence in your adhesive’s durability.

Document Your Progress and Plan for Future Uses

Keeping detailed records of your testing results and application processes is essential for tracking progress and identifying areas for improvement. By documenting your experiences, you can better assess your adhesive’s product durability and adhesive flexibility under heat. This helps you refine techniques and choose the best adhesives for future projects. Your records should include notes on how each adhesive performed, any signs of wear, and how well it maintained flexibility under stress. With clear documentation, you’ll develop a tailored plan for future uses, ensuring reliable, long-lasting bonds. Stay motivated by tracking your successes and setbacks, knowing each step brings you closer to mastering heat-tolerant adhesives.

- Feel confident in your ability to choose the right product every time

- Recognize patterns that lead to stronger, more durable bonds

- Stay motivated by celebrating your progress

- Avoid repeating mistakes that compromise product durability

- Build a solid foundation for future adhesive projects

Frequently Asked Questions

How Long Does It Typically Take for Heat Tolerant Adhesives to Cure?

Heat tolerant adhesives typically take between 24 to 48 hours to fully cure, but curing time can vary depending on temperature influence. If you work in higher temperatures, curing speeds up; cooler environments may extend it. Keep in mind, some adhesives reach initial strength sooner, often within a few hours, but for maximum durability, it’s best to allow the full curing period specified by the manufacturer.

Can Heat Tolerant Adhesives Be Used on Plastic Surfaces?

Yes, heat tolerant adhesives work well for plastic bonding. To guarantee a strong bond, you need to prepare the surface properly by cleaning and roughening it, removing any dirt or oils. This enhances adhesion and prevents slipping. Select an adhesive compatible with your plastic type, apply it evenly, and follow curing instructions. Proper surface preparation and choosing the right adhesive are key to successful plastic bonding with heat tolerant adhesives.

Are There Environmental Conditions That Affect Adhesive Performance?

Did you know that 60% of adhesive failures are linked to environmental factors? Yes, environmental conditions like humidity, temperature fluctuations, and UV exposure directly influence adhesive durability. These factors can weaken bonds over time, reducing performance. To guarantee your heat tolerant adhesives last, you need to take into account environmental factors and select products designed for specific conditions. Proper preparation and application are also key to maintaining ideal adhesive durability.

How Do I Remove Excess Adhesive Safely After Application?

To remove excess adhesive safely, start by wearing safety precautions like gloves and eye protection. Use a clean cloth or plastic scraper to gently clean residue without damaging surfaces. For stubborn spots, apply a solvent recommended by the adhesive manufacturer, ensuring proper ventilation. Always follow safety guidelines when handling chemicals, and test any cleaner on a small area first to prevent damage or unintended reactions.

What Are Common Mistakes to Avoid When Using Heat Resistant Adhesives?

Imagine you’re attaching a heat-resistant panel, but skip surface preparation—that’s a common mistake to avoid. Application errors like rushing the process or not following manufacturer instructions can lead to weak bonds. Always guarantee surfaces are clean and dry before applying heat resistant adhesives. This prevents issues like poor adhesion or uneven curing, ultimately saving you time and money. Proper surface prep and careful application are key to success.

Conclusion

So, you’ve mastered heat-tolerant adhesives in just a weekend—who knew bonding under intense heat could be so effortless? Now, with your newfound expertise, you’re practically a DIY superhero. Just don’t forget, despite all your preparation, a fiery oven might still outsmart your skills. But hey, if your adhesives can handle the heat, maybe you can too. Happy bonding—and remember, the only thing hotter than your project is your confidence!