If you’re wondering about heat tolerant adhesives, these are special glues designed to stay strong and flexible in high temperatures. They manage how materials expand with heat and resist breaking down or peeling over time. Knowing their ratings, types, and labels helps you pick the right one for your project. If you want to understand what makes some adhesives more heat-resistant than others, keep exploring to learn more about their features and uses.

Key Takeaways

- Heat tolerant adhesives are specially formulated to retain strength and flexibility when exposed to high temperatures.

- They are classified by temperature resistance ratings based on standardized testing protocols.

- Common types include epoxy, silicone, and polyimide adhesives, each suited for different high-heat applications.

- The main difference between “heat-resistant” and “high-temperature” adhesives is their ability to endure prolonged heat versus short-term exposure.

- Performance depends on factors like thermal expansion, substrate properties, and environmental conditions, ensuring durability in demanding environments.

What Are Heat Tolerant Adhesives?

Have you ever wondered how certain adhesives withstand high temperatures without losing their strength? Heat tolerant adhesives are specially formulated to endure extreme heat, making them ideal for demanding applications. They are designed to manage thermal expansion, so they don’t crack or peel when exposed to temperature fluctuations. One key factor is adhesive viscosity; these adhesives maintain the right thickness to stay effective under heat, preventing them from becoming too runny or too stiff. This stability ensures they bond securely even in hot environments. Whether used in automotive, aerospace, or industrial settings, heat tolerant adhesives are crafted to maintain their integrity where standard glues would fail. Their unique properties make them essential for high-temperature applications demanding reliable, long-lasting bonds. Additionally, understanding Kia Tuning options can help optimize vehicle performance under various conditions, including high heat environments.

Understanding Temperature Resistance Ratings

Understanding temperature resistance ratings helps you choose the right adhesive for your needs. These ratings are based on specific temperature classifications and testing standards that guarantee reliability. By knowing how adhesives are tested and classified, you can make more informed decisions for your projects. Additionally, detecting passive voice in your writing can improve clarity and effectiveness.

Temperature Classifications

Temperature classifications provide a clear way to compare the heat resistance of different adhesives. They help you understand how well an adhesive maintains its properties under heat exposure, considering factors like thermal expansion and temperature stability. These ratings categorize adhesives into different classes based on their maximum continuous operating temperature. For example, an adhesive rated for high temperatures will resist softening or degrading when exposed to heat over time. Recognizing how conflicting requirements can influence adhesive performance is crucial for selecting the right product. Some key points include: – Recognizing how thermal expansion affects bond integrity at various temperatures – Understanding the importance of temperature stability for long-term applications – Comparing classifications to select the right adhesive for your heat-sensitive project

Testing Standards Explained

To accurately determine an adhesive’s heat resistance, standardized testing methods are employed that simulate real-world conditions. These tests often measure how well the adhesive bonding holds up under high temperatures, considering factors like thermal expansion that can cause stress and possible failure. You’ll find that testing standards specify temperature ranges, durations, and environmental conditions to guarantee consistency. During testing, the adhesive’s ability to maintain its bond strength despite thermal expansion is vital, especially in heat-tolerant applications. These standards help you understand a product’s temperature resistance ratings, giving you confidence in its performance. By following these protocols, manufacturers can reliably compare adhesives and ensure they meet specific heat tolerance requirements for your needs. Additionally, testing protocols ensure that adhesives are evaluated under conditions that mimic actual use environments, further validating their heat resistance.

Common Types of Heat-Resistant Adhesives

When selecting heat-resistant adhesives, it’s crucial to know the common types designed to withstand high temperatures. These adhesives are engineered to handle thermal expansion and maintain adhesive flexibility, preventing cracks or failures.

- Epoxy adhesives: Known for their high strength and temperature resistance, they work well in demanding environments.

- Silicone-based adhesives: These offer excellent flexibility and can tolerate extreme heat without losing adhesion.

- Polyimide adhesives: Designed for high-performance applications, they resist thermal expansion and maintain stability at very high temperatures.

Understanding these types helps you choose the right adhesive for your needs, ensuring durability and performance. Each type has unique properties that address specific challenges posed by heat, such as expansion and the need for flexibility.

Considering the heat tolerance of an adhesive can significantly impact its effectiveness in high-temperature applications.

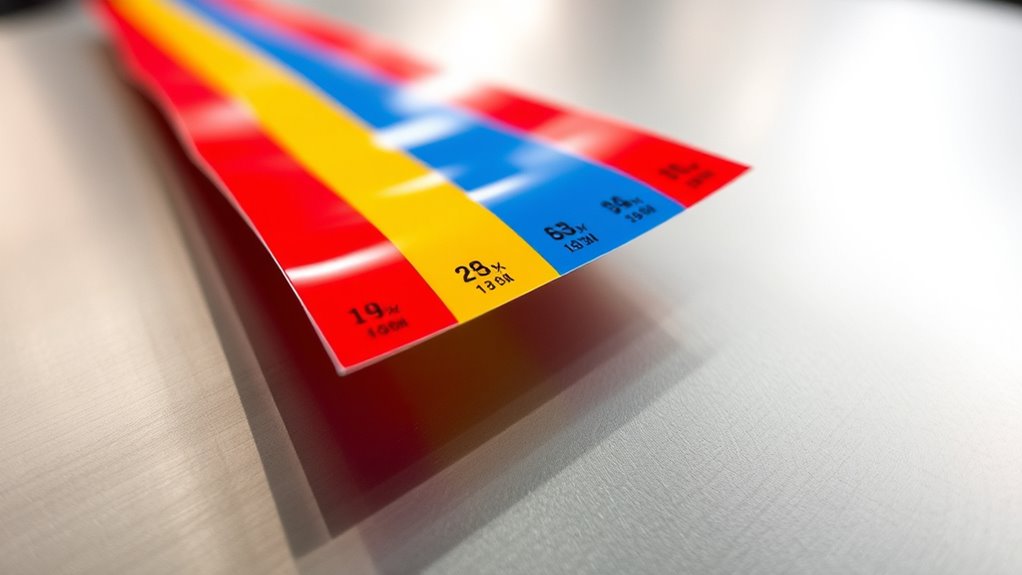

How to Read Adhesive Labels and Specifications

Have you ever struggled to understand what adhesive labels really mean? Reading labels can be confusing, but learning to interpret adhesive color codes and packaging symbols makes it easier. Color codes often indicate temperature resistance or specific properties, so pay attention to the colors used. Packaging symbols provide quick info about application methods, curing times, or safety precautions. For example, a flame symbol might show heat resistance, while a clock indicates curing duration. Always check the technical datasheet for detailed specifications, but labels give a helpful overview. Understanding the support hours for related entertainment venues can also help plan your projects around available assistance. By familiarizing yourself with these symbols and color codes, you ensure you select the right adhesive for your heat-tolerant needs and avoid mistakes that could compromise your project’s durability.

The Significance of “High-Temperature” and “Heat-Resistant” Terms

Understanding what “high-temperature” and “heat-resistant” really mean helps you select the right adhesive for your project. You need to know the specific temperature ranges they cover and how their capabilities differ. This knowledge ensures you pick an adhesive that performs reliably under your application’s conditions. Additionally, considering the safety features of electric heated mattress pads can help prevent overheating and ensure safe use of heated bedding.

Clarifying “High-Temperature” Range

What exactly qualifies an adhesive as “high-temperature” or “heat-resistant”? It depends on how well it withstands specific temperature ranges without losing strength or flexibility. Typically, this involves understanding:

- The maximum temperature the adhesive can handle without degrading

- Its ability to resist thermal expansion caused by temperature fluctuations

- How it maintains adhesion under prolonged heat exposure

These factors determine whether an adhesive is suitable for demanding environments. For example, adhesives rated for high temperatures must tolerate thermal expansion without cracking or losing adhesion. Keep in mind, the “high-temperature” range varies across products, often from 200°C to over 500°C, depending on the formulation. Knowing these parameters helps ensure your adhesive performs reliably in heat-intensive applications. Additionally, considering thermal stability is crucial, as it indicates how well an adhesive maintains its properties under sustained high temperatures.

Distinguishing “Heat-Resistant” Capabilities

Ever wonder what truly sets apart “heat-resistant” adhesives from those simply labeled as “high-temperature”? The key difference lies in their ability to handle thermal expansion without losing adhesion or cracking. “Heat-resistant” adhesives maintain their bond and flexibility under prolonged exposure to high heat, ensuring long-term adhesive durability. In contrast, adhesives marked only as “high-temperature” may tolerate short-term heat but could weaken over time as thermal expansion causes stress at the bond line. Understanding this distinction helps you select the right adhesive for demanding environments. Heat-resistant adhesives are designed to accommodate thermal expansion without degrading, keeping the bond intact even when temperatures fluctuate. This capability is essential for applications where long-lasting durability under heat is fundamental. Proper adhesive selection is crucial to ensure reliable performance in high-heat conditions, especially in environments with frequent temperature changes.

Practical Application Differences

The terms “high-temperature” and “heat-resistant” adhesives have distinct practical implications, which directly impact their suitability for different applications. “High-temperature” adhesives may briefly withstand elevated heat levels, making them suitable for short-term or less demanding tasks. However, they often face application challenges when used in continuous high-heat environments. “Heat-resistant” adhesives are designed for long-term durability under sustained heat, making them ideal for industry-specific uses like aerospace, electronics, or automotive industries. When choosing between them, consider:

- The duration of heat exposure in your application

- The specific industry requirements

- Potential application challenges related to adhesive longevity and performance

- Proper selection of adhesive type is critical to ensure safety and effectiveness in high-heat environments.

Factors Affecting Adhesive Performance at High Temperatures

When exposed to high temperatures, the performance of adhesives depends on several critical factors. One key factor is thermal expansion; materials expand at different rates, which can create stress at the bond line, weakening the adhesive. Additionally, high heat can accelerate adhesive degradation, breaking down chemical bonds and reducing strength over time. The adhesive’s formulation determines its ability to withstand thermal expansion without cracking or losing adhesion. The substrate’s properties also matter, as some materials expand or contract more than others, affecting overall performance. Environmental conditions like humidity and exposure to chemicals can further influence how well an adhesive performs under heat. Understanding these factors helps you choose adhesives that maintain their strength and stability in high-temperature environments.

Tips for Choosing the Right Heat-Resistant Adhesive

Choosing the right heat-resistant adhesive requires understanding your specific application needs and the conditions it will face. Consider how thermal expansion might affect adhesion, as materials expand and contract with temperature changes. You’ll also want an adhesive with the right flexibility to accommodate these movements without cracking or failing. To select the best option, keep these tips in mind:

Selecting a heat-resistant adhesive involves matching thermal tolerance and flexibility to withstand temperature-induced material movements.

- Match the adhesive’s thermal tolerance to your operating temperature range

- Choose an adhesive with adequate flexibility for thermal expansion and contraction

- Guarantee compatibility with the materials you’re bonding, considering their thermal properties

Frequently Asked Questions

Can Heat-Tolerant Adhesives Withstand Sudden Temperature Changes?

Yes, heat-tolerant adhesives can often withstand sudden temperature changes, but it depends on the specific formulation. Many are designed to resist thermal shock, which occurs during rapid temperature fluctuations. When exposed to quick shifts, these adhesives maintain their strength and adhesion. However, extreme or repeated rapid temperature changes might weaken some formulations over time, so always choose an adhesive suited for your specific thermal conditions.

Are There Environmentally Friendly Heat-Resistant Adhesive Options?

Yes, environmentally friendly heat-resistant adhesives are available. You can choose biodegradable adhesives or plant-based glues that withstand high temperatures while reducing environmental impact. These options are crafted from natural materials, making them safer for the planet. When selecting an adhesive, look for labels indicating eco-friendliness and heat resistance, ensuring you get a sustainable solution that meets your needs without harming the environment.

How Long Do Heat-Resistant Adhesives Maintain Their Strength?

Imagine your adhesive as a sturdy bridge, holding strong through heat’s relentless push. Typically, heat-resistant adhesives maintain their strength for several years, with adhesive durability and heat adhesive lifespan varying based on usage and environment. When properly applied, they can withstand high temperatures for extended periods, often 5 to 10 years or more. Regular checks guarantee your bond remains resilient, just like a well-maintained bridge standing tall against time and heat.

Do Different Substrates Require Different Heat-Tolerant Adhesives?

Yes, different substrates often require different heat-tolerant adhesives because substrate compatibility affects material bonding. You need to select an adhesive specifically designed for the materials you’re working with, such as metal, plastic, or ceramic, to guarantee a strong bond under heat. Using the right adhesive ensures peak performance, prevents bond failure, and maintains durability even in high-temperature environments. Always check the adhesive’s compatibility with your substrate for the best results.

Can Heat-Resistant Adhesives Be Used in Underwater or Moist Conditions?

You might wonder if heat-resistant adhesives can handle underwater or moist environments. The answer is yes, but only if they’re specially formulated for waterproof bonding and moisture resistance. These adhesives are designed to withstand water exposure while maintaining their heat tolerance. If you need a reliable bond in such conditions, choose a product explicitly labeled for underwater use. Don’t settle for less—your project’s success depends on it.

Conclusion

Choosing the right heat-tolerant adhesive is like finding the perfect tool for a tough job—you need the right fit to get it done. By understanding temperature ratings and labels, you can confidently select an adhesive that withstands high heat without failing. Remember, just as a thermostat controls the heat, your knowledge controls your success in selecting the right adhesive. With these tips, you’re well-equipped to make smart, heat-resistant choices every time.